What is the internal structure of the propeller blades of low altitude aircraft impeller blades?

Release Time : 2024-12-15

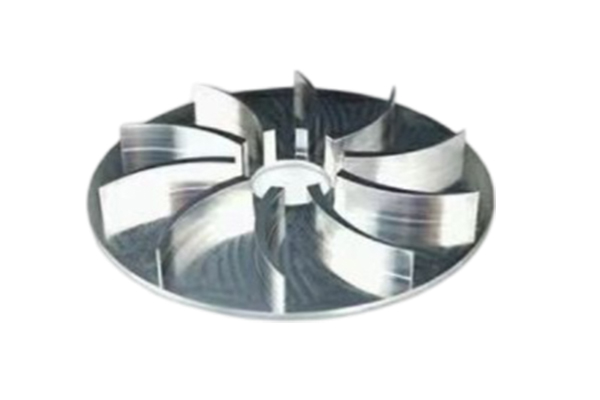

The internal structure of the propeller blades of low altitude aircraft impeller blades is exquisitely and complexly designed to ensure efficient and stable operation under various working conditions.

It is usually equipped with a reinforcement structure to improve the strength and rigidity of the blades. Common ones are the reinforcement ribs arranged along the length of the blades. These reinforcement ribs are mostly made of high-strength metal materials, such as titanium alloy or alloy steel. They are reasonably arranged according to the force analysis of the blades. When subjected to huge centrifugal forces, aerodynamic loads and torsional forces, they can effectively disperse stress and prevent the blades from bending, deforming or breaking. For example, in some high-performance low altitude aircraft impeller blades propeller blades, the reinforcement ribs are arranged in a specific grid shape, so that the blades can be well supported in all directions to ensure flight safety.

Some low altitude aircraft impeller blades propeller blades adopt a hollow design. The hollow part not only reduces the overall weight of the blade, which is conducive to improving the fuel economy and maneuverability of the aircraft, but also provides space for the placement of other functional components. For example, a sensor network for monitoring the working status of the blades can be built in to collect key data such as blade stress, temperature, vibration frequency, etc. in real time, and feedback to the aircraft control system through a wireless transmission system. In this way, the pilot can grasp the operating status of the propeller in time so that he can take countermeasures quickly when an abnormality occurs, which greatly enhances the reliability of flight.

In some advanced low altitude aircraft impeller blades, there is also a composite system of composite materials and metal structures. The external composite material layer, such as carbon fiber reinforced composite materials, has excellent fatigue resistance and lightweight characteristics, which can effectively reduce aerodynamic drag; while the internal metal core or skeleton provides the necessary strength foundation, especially in areas such as the root of the blade that bear high loads. The two are closely combined and complement each other, so that the blades can optimize performance to the greatest extent while ensuring sufficient strength.

In addition, in order to ensure the stability and reliability of the internal structure, there are also extremely high requirements for the manufacturing process. Precision molding processes, such as precision casting, CNC machining, and advanced composite material laying processes, are used to strictly control the dimensional accuracy and assembly quality of each component to avoid problems such as stress concentration or structural looseness caused by manufacturing defects. In short, the internal structure of low altitude aircraft impeller blades is the product of the perfect combination of mechanical principles, material science and manufacturing technology, which lays a solid foundation for the safe flight and efficient operation of the aircraft.