How does the application of new materials in auto parts and accessories processing promote the sustainable development of the industry?

Release Time : 2024-12-02

With the rapid development of science and technology and the increasing awareness of environmental protection, the auto parts and accessories processing industry is facing unprecedented challenges and opportunities. In this context, the application of new materials has become an important force in promoting the sustainable development of the industry. New materials not only provide better performance for auto parts and accessories, but also help reduce production costs and reduce environmental pollution, thereby achieving a win-win situation of economic and ecological benefits.

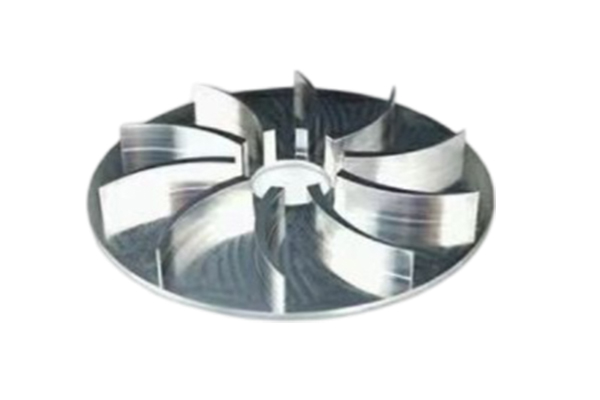

In the processing of auto parts and accessories, the application of new materials has significantly improved the quality and performance of products. For example, lightweight and high-strength materials such as aluminum alloy, carbon fiber, etc. not only reduce the overall weight of the car and improve fuel efficiency, but also enhance the rigidity and impact resistance of the car. The application of these materials makes cars safer, more energy-saving and environmentally friendly, and meets the needs of modern consumers for high-quality cars.

The application of new materials also promotes the innovation and development of the auto parts and accessories processing industry. Traditional materials have certain limitations in performance, but the emergence of new materials breaks these limitations and provides designers and engineers with more choices. They can select appropriate materials, optimize design solutions, and improve production efficiency based on the specific needs of the product. This innovation not only promotes the advancement of auto parts and accessories processing technology, but also promotes the upgrading of the entire automotive industry.

In terms of environmental protection, the application of new materials also plays an important role. Some renewable materials, such as bio-based plastics, can replace traditional petroleum-based materials, reducing dependence on limited resources and reducing carbon emissions. The application of these materials in auto parts and accessories helps reduce environmental pollution in the automobile manufacturing process and achieve green production. In addition, the recycling and reuse technology of new materials is also constantly developing, further reducing resource waste and environmental pollution.

However, the application of new materials also faces some challenges. For example, the high R&D and production costs of some high-performance materials limit their widespread application in the processing of auto parts and accessories. At the same time, the processing technology and processes of new materials also need to be continuously developed and improved to meet the needs of mass production. Therefore, governments, enterprises and scientific research institutions need to strengthen cooperation to jointly promote the research and development and application of new materials, reduce production costs and improve production efficiency.

In summary, the application of new materials is of great significance to the sustainable development of the auto parts and accessories processing industry. It not only improves product quality and performance and promotes industry innovation and development, but also helps reduce environmental pollution and achieve green production.

In the processing of auto parts and accessories, the application of new materials has significantly improved the quality and performance of products. For example, lightweight and high-strength materials such as aluminum alloy, carbon fiber, etc. not only reduce the overall weight of the car and improve fuel efficiency, but also enhance the rigidity and impact resistance of the car. The application of these materials makes cars safer, more energy-saving and environmentally friendly, and meets the needs of modern consumers for high-quality cars.

The application of new materials also promotes the innovation and development of the auto parts and accessories processing industry. Traditional materials have certain limitations in performance, but the emergence of new materials breaks these limitations and provides designers and engineers with more choices. They can select appropriate materials, optimize design solutions, and improve production efficiency based on the specific needs of the product. This innovation not only promotes the advancement of auto parts and accessories processing technology, but also promotes the upgrading of the entire automotive industry.

In terms of environmental protection, the application of new materials also plays an important role. Some renewable materials, such as bio-based plastics, can replace traditional petroleum-based materials, reducing dependence on limited resources and reducing carbon emissions. The application of these materials in auto parts and accessories helps reduce environmental pollution in the automobile manufacturing process and achieve green production. In addition, the recycling and reuse technology of new materials is also constantly developing, further reducing resource waste and environmental pollution.

However, the application of new materials also faces some challenges. For example, the high R&D and production costs of some high-performance materials limit their widespread application in the processing of auto parts and accessories. At the same time, the processing technology and processes of new materials also need to be continuously developed and improved to meet the needs of mass production. Therefore, governments, enterprises and scientific research institutions need to strengthen cooperation to jointly promote the research and development and application of new materials, reduce production costs and improve production efficiency.

In summary, the application of new materials is of great significance to the sustainable development of the auto parts and accessories processing industry. It not only improves product quality and performance and promotes industry innovation and development, but also helps reduce environmental pollution and achieve green production.