How to ensure the accuracy and surface quality of semiconductor equipment precision parts

Release Time : 2025-02-24

The precision and surface quality of semiconductor equipment precision parts are the key factors to ensure their performance stability.

High-precision mold design is the premise to ensure the precision of semiconductor equipment precision parts. Using advanced computer-aided design (CAD) technology, the mold is finely designed to ensure the accuracy of mold size and shape. At the same time, the shrinkage rate of the material is fully considered, and the mold size is compensated through precise calculation and simulation analysis to ensure that the size deviation of the part after injection molding is controlled within a very small range.

High-quality raw materials are the basis for manufacturing high-precision and low-surface defect parts. Select raw materials that have been strictly purified to ensure that the impurity content is extremely low and avoid the influence of impurities on the precision and surface quality of parts. At the same time, the raw material supplier is required to provide a detailed material performance report and conduct random inspections on each batch of materials to ensure the consistency and stability of material performance.

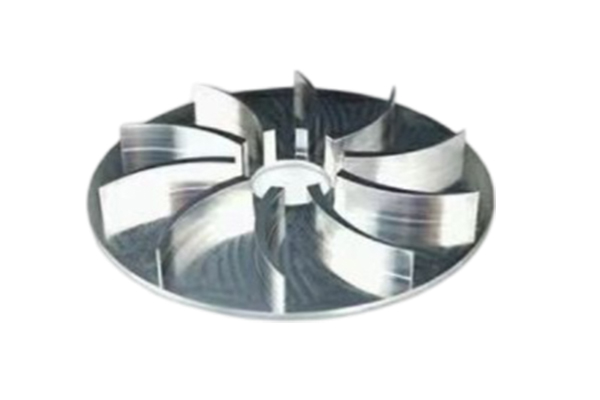

Advanced manufacturing technology and high-precision processing equipment are the key to ensuring part precision. Use high-precision processing technologies such as five-axis linkage machining centers and electric discharge machining (EDM) to ensure the dimensional accuracy and shape accuracy of parts during processing. At the same time, the processing equipment is regularly maintained and calibrated to ensure that the processing accuracy of the equipment is always maintained at a high level.

Strict injection molding process control is an important link to ensure the precision and surface quality of parts. Accurately control parameters such as temperature, pressure, speed, etc. during the injection molding process to ensure that the material melts and flows evenly and avoid molding defects caused by uneven temperature. At the same time, optimize the cooling process to ensure that the cooling speed of each part of the mold is consistent and reduce component deformation caused by uneven cooling.

Surface treatment technology is crucial to improving the surface quality of parts. Use surface treatment technologies such as sandblasting, polishing, and electroplating to remove tiny defects and impurities on the surface of parts and improve the surface finish and flatness. At the same time, according to the use environment and requirements of the parts, select appropriate surface coating materials and technologies to improve the corrosion resistance and wear resistance of the parts.

Strict quality inspection is an effective means to ensure the precision and surface quality of parts. Use advanced testing equipment and methods, such as three-coordinate measuring machines, optical microscopes, etc., to conduct comprehensive inspections on the size, shape, surface quality, etc. of parts. For unqualified parts, rework or scrap them in time to ensure that all parts shipped meet quality requirements.

Through high-precision mold design, high-quality raw material selection, advanced manufacturing technology and high-precision processing equipment, strict injection molding process control, effective surface treatment technology, strict quality inspection, and continuous improvement and optimization of production processes, we can ensure that the accuracy and surface quality of semiconductor equipment precision parts meet the requirements.