Lightweight technology breakthroughs for new energy Auto Parts And Accessories

Release Time : 2024-11-07

In the wave of new energy vehicle development, lightweight technology for spare parts has become a key research field, and its breakthroughs are mainly concentrated in the following aspects.

First, material innovation is one of the core breakthroughs. New composite materials have great potential in the manufacture of new energy Auto Parts And Accessories. For example, carbon fiber reinforced composite materials have higher strength than steel, but much lower density than steel. Applying them to large spare parts such as body frames and chassis can significantly reduce weight while ensuring strength. In addition, magnesium alloy is also a very promising material. Its density is lower than that of aluminum alloy, and it has good shock absorption performance and processability. It is suitable for manufacturing spare parts such as car seat frames and instrument panel brackets, which helps to further reduce the weight of the whole vehicle and increase the cruising range.

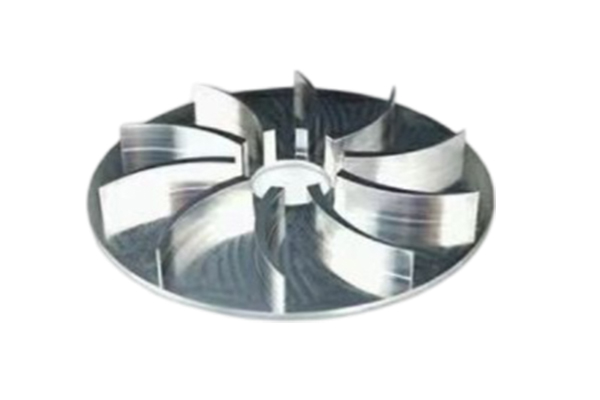

Secondly, structural optimization is an important breakthrough direction. Through topological optimization design, the internal structure of spare parts can be redesigned according to the stress conditions of spare parts in actual use. For example, in the design of the battery pack shell, unnecessary materials are removed to make the stress distribution more reasonable and reduce the weight without affecting the protection of the battery function. For the rotor and stator structure of the motor, a new topological structure can also be adopted to reduce the accumulation of excess materials, improve the power density and efficiency of the motor, and achieve lightweight at the same time.

Furthermore, the improvement of manufacturing process provides support for lightweight. Advanced 3D printing technology has emerged in the manufacturing of new energy Auto Parts And Accessories. It can realize one-time molding of complex geometric shapes, reducing the additional materials and weight required for connection, assembly and other links in traditional manufacturing processes. For example, some parts with complex internal cooling channels can be accurately manufactured through 3D printing, which reduces the weight while ensuring the heat dissipation function. In addition, lightweight connection technology should not be ignored. For example, using high-strength adhesives or new riveting technology instead of traditional bolt connections can reduce the weight of the connection parts while ensuring the connection strength.

Finally, system integration is also a breakthrough point for lightweight. Integrating multiple functional parts into one module reduces the number of parts and the total weight. For example, integrating the drive motor, reducer and controller to form an electric drive assembly can not only optimize the spatial layout, but also reduce the weight by sharing the shell and other methods, and improve the efficiency and compactness of the entire power system. In short, innovation in every link, from materials, structures, processes to system integration, may become a key breakthrough in the lightweight technology of new energy Auto Parts And Accessories.

First, material innovation is one of the core breakthroughs. New composite materials have great potential in the manufacture of new energy Auto Parts And Accessories. For example, carbon fiber reinforced composite materials have higher strength than steel, but much lower density than steel. Applying them to large spare parts such as body frames and chassis can significantly reduce weight while ensuring strength. In addition, magnesium alloy is also a very promising material. Its density is lower than that of aluminum alloy, and it has good shock absorption performance and processability. It is suitable for manufacturing spare parts such as car seat frames and instrument panel brackets, which helps to further reduce the weight of the whole vehicle and increase the cruising range.

Secondly, structural optimization is an important breakthrough direction. Through topological optimization design, the internal structure of spare parts can be redesigned according to the stress conditions of spare parts in actual use. For example, in the design of the battery pack shell, unnecessary materials are removed to make the stress distribution more reasonable and reduce the weight without affecting the protection of the battery function. For the rotor and stator structure of the motor, a new topological structure can also be adopted to reduce the accumulation of excess materials, improve the power density and efficiency of the motor, and achieve lightweight at the same time.

Furthermore, the improvement of manufacturing process provides support for lightweight. Advanced 3D printing technology has emerged in the manufacturing of new energy Auto Parts And Accessories. It can realize one-time molding of complex geometric shapes, reducing the additional materials and weight required for connection, assembly and other links in traditional manufacturing processes. For example, some parts with complex internal cooling channels can be accurately manufactured through 3D printing, which reduces the weight while ensuring the heat dissipation function. In addition, lightweight connection technology should not be ignored. For example, using high-strength adhesives or new riveting technology instead of traditional bolt connections can reduce the weight of the connection parts while ensuring the connection strength.

Finally, system integration is also a breakthrough point for lightweight. Integrating multiple functional parts into one module reduces the number of parts and the total weight. For example, integrating the drive motor, reducer and controller to form an electric drive assembly can not only optimize the spatial layout, but also reduce the weight by sharing the shell and other methods, and improve the efficiency and compactness of the entire power system. In short, innovation in every link, from materials, structures, processes to system integration, may become a key breakthrough in the lightweight technology of new energy Auto Parts And Accessories.