How did the Low Altitude Aircraft Impeller Blades become the technological wings that dance in the sky?

Release Time : 2024-08-29

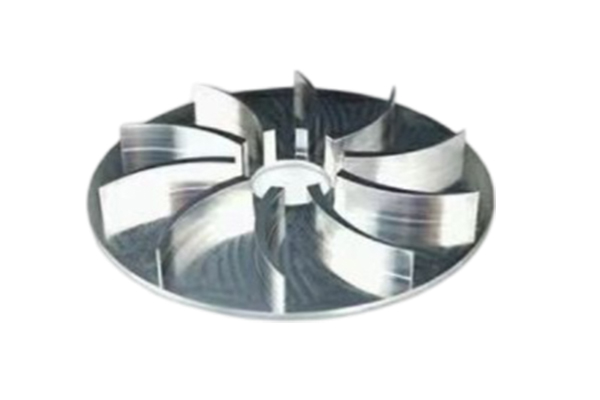

As one of the key components of the aircraft, the design and technical level of the Low Altitude Aircraft Impeller Blades have a direct impact on the performance of the aircraft and the flying experience. Their performance in low-altitude flight not only involves flight stability and efficiency, but also reflects the advanced level of modern technology.

1. Design and material technology

Efficient aerodynamic design:

The design of the Low Altitude Aircraft Impeller Blades focuses on aerodynamic performance, reducing aerodynamic drag and increasing lift through precise shape and structural design. Modern computational fluid dynamics (CFD) and wind tunnel testing technology can optimize the aerodynamic performance of the blades, making them perform well in low-altitude flight.

Application of advanced materials:

The use of lightweight and high-strength materials such as carbon fiber composites or titanium alloys can significantly reduce the weight of the blades while improving their fatigue resistance and strength. The application of these materials not only improves the performance of the blades, but also extends their service life.

Durability and resistance to environmental influences:

During low-altitude flight, the blades may encounter environmental factors such as dust and moisture. Therefore, modern blade designs also include anti-corrosion and anti-wear technologies to ensure their reliability and stability under various environmental conditions.

2. Power system and performance

Efficient power transmission:

The power transmission between the impeller blades and the engine must be efficient and stable. Modern low-altitude aircraft use advanced engine control systems and variable pitch technology to adjust the angle of the blades according to the flight status, thereby optimizing thrust and fuel efficiency.

Dynamic adjustment technology:

Advanced dynamic adjustment technology enables the blades to automatically adjust their angles during flight to adapt to different flight requirements and environmental conditions. This technology not only improves the stability of flight, but also improves the maneuverability and responsiveness of the aircraft.

3. Safety and stability

Fault detection and self-repair technology:

Modern blade designs integrate intelligent fault detection systems that can monitor the status of the blades in real time and warn of potential faults. This technology can improve flight safety and reduce maintenance and downtime.

Structural optimization and load distribution:

Through advanced structural optimization technology, the blades can effectively distribute loads while ensuring strength. This optimized design helps reduce vibration and noise and improve flight comfort.

4. Innovation and Future Trends

Intelligent Control and Adaptive Systems:

Future low-altitude aircraft blades may integrate more intelligent control systems, such as flight optimization algorithms based on artificial intelligence, which will enable the blades to make adaptive adjustments based on real-time data during flight, thereby achieving more precise flight control.

Green Technology Application:

In terms of environmental protection, the design of low-altitude aircraft blades will also gradually adopt green technology. For example, the development of more efficient noise control technology and more environmentally friendly materials will help reduce the impact of flight on the environment.

Modular Design

Future blades may adopt a modular design to make their maintenance and replacement more convenient. This design not only reduces maintenance costs, but also improves the operating efficiency of aircraft.

As an important part of modern aircraft, Low Altitude Aircraft Impeller Blades have become technological wings dancing in the sky through precise design, advanced material technology and intelligent control systems. Their efficiency, safety and stability in flight reflect the progress of modern aviation technology.

1. Design and material technology

Efficient aerodynamic design:

The design of the Low Altitude Aircraft Impeller Blades focuses on aerodynamic performance, reducing aerodynamic drag and increasing lift through precise shape and structural design. Modern computational fluid dynamics (CFD) and wind tunnel testing technology can optimize the aerodynamic performance of the blades, making them perform well in low-altitude flight.

Application of advanced materials:

The use of lightweight and high-strength materials such as carbon fiber composites or titanium alloys can significantly reduce the weight of the blades while improving their fatigue resistance and strength. The application of these materials not only improves the performance of the blades, but also extends their service life.

Durability and resistance to environmental influences:

During low-altitude flight, the blades may encounter environmental factors such as dust and moisture. Therefore, modern blade designs also include anti-corrosion and anti-wear technologies to ensure their reliability and stability under various environmental conditions.

2. Power system and performance

Efficient power transmission:

The power transmission between the impeller blades and the engine must be efficient and stable. Modern low-altitude aircraft use advanced engine control systems and variable pitch technology to adjust the angle of the blades according to the flight status, thereby optimizing thrust and fuel efficiency.

Dynamic adjustment technology:

Advanced dynamic adjustment technology enables the blades to automatically adjust their angles during flight to adapt to different flight requirements and environmental conditions. This technology not only improves the stability of flight, but also improves the maneuverability and responsiveness of the aircraft.

3. Safety and stability

Fault detection and self-repair technology:

Modern blade designs integrate intelligent fault detection systems that can monitor the status of the blades in real time and warn of potential faults. This technology can improve flight safety and reduce maintenance and downtime.

Structural optimization and load distribution:

Through advanced structural optimization technology, the blades can effectively distribute loads while ensuring strength. This optimized design helps reduce vibration and noise and improve flight comfort.

4. Innovation and Future Trends

Intelligent Control and Adaptive Systems:

Future low-altitude aircraft blades may integrate more intelligent control systems, such as flight optimization algorithms based on artificial intelligence, which will enable the blades to make adaptive adjustments based on real-time data during flight, thereby achieving more precise flight control.

Green Technology Application:

In terms of environmental protection, the design of low-altitude aircraft blades will also gradually adopt green technology. For example, the development of more efficient noise control technology and more environmentally friendly materials will help reduce the impact of flight on the environment.

Modular Design

Future blades may adopt a modular design to make their maintenance and replacement more convenient. This design not only reduces maintenance costs, but also improves the operating efficiency of aircraft.

As an important part of modern aircraft, Low Altitude Aircraft Impeller Blades have become technological wings dancing in the sky through precise design, advanced material technology and intelligent control systems. Their efficiency, safety and stability in flight reflect the progress of modern aviation technology.